Introduction

The DQ200 7-speed dual clutch gearbox (gearbox code 0AM) is one of the most widely used VW Group transmissions — fitted to everything from the Polo and Golf to the Audi A1 and Skoda Octavia.

Although efficient and compact, the DQ200 can suffer from a specific issue where the gearbox crunches or scrapes when shifting into 3rd gear, particularly between 2nd–3rd or 4th–3rd transitions.

At Eco Torque, we’ve seen this fault first-hand in our workshop and have developed a proven method of diagnosis and repair to restore smooth shifting and prevent repeat failure.

Symptoms — What Drivers Notice

Owners experiencing this problem typically report one or more of the following:

- Scraping or crunching noise when the gearbox shifts from 2nd to 3rd or 4th to 3rd gear

- Noise occurs in both automatic and manual Tiptronic mode

- Transmission warning light appears on the dashboard

- Gearbox may hesitate or struggle to select 3rd gear

- Harsh or jerky engagement during low-speed gear changes

These symptoms tend to worsen gradually, particularly in higher-mileage vehicles or those used mainly in urban traffic.

Confirmed Fault Codes

When this issue occurs, the following fault codes are often stored in the gearbox control unit (TCU):

Fault Code - Description

- P072C00: Stuck in Gear 1

- P074B00: Unable to Engage Gear 3

- P086800: Transmission Fluid Pressure Low

- P177900: Transmission Input Shaft 1 Overspeed

These symptoms tend to worsen gradually, particularly in higher-mileage vehicles or those used mainly in urban traffic.

Confirmed Fault Codes

When this issue occurs, the following fault codes are often stored in the gearbox control unit (TCU):

Fault Code – Description

- P072C00: Stuck in Gear 1

- P074B00: Unable to Engage Gear 3

- P086800: Transmission Fluid Pressure Low

- P177900: Transmission Input Shaft 1 Overspeed

Workshop Findings

In most cases, our technicians are able to reproduce the issue during a road test. Diagnostic inspection commonly reveals one or more of the following stored conditions:

- P177900: Input shaft 1 excessive revs

- P072C00: Gear 1 not adjustable

- P074B00: 3rd gear synchronisation failed

- P086800: Gearbox pressure adaptation on stop

These findings point toward synchromesh and selector fork wear, not mechatronic malfunction.

Root Cause — Why It Happens

The cause is traced to a production-related deviation in the 3rd-gear synchromesh assembly on certain 0AM DQ200 transmissions.

This results in:

- Poor engagement of 3rd gear, leading to crunching and scraping

- Metal swarf generation inside the gearbox from the worn components

- Gradual contamination of the magnets the mechatronic reads from and fluid system

Eco Torque Repair Procedure

When this fault is confirmed, we carry out the following steps to repair the gearbox and prevent recurrence:

1. Diagnostic Verification

We confirm the fault codes and reproduce the symptoms through live data testing and controlled shift evaluation.

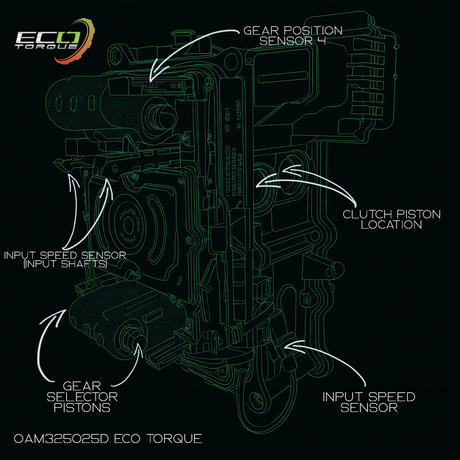

2. Mechatronic Removal & Inspection

The mechatronic unit is removed and inspected for signs of metal swarf on the selector magnets. If present, the system is thoroughly cleaned.

3. Internal Gearbox Check

Before replacing any components, the following checks are made:

- Bearings inspected for pitting or excessive wear

- Selector fork for 1st/3rd gear checked for distortion or damage

- 3rd-gear synchromesh examined for shortened or worn locking collar teeth

4. Component Replacement

If the above faults are present, we replace:

- Selector fork for 1st/3rd gear

- Synchromesh for 3rd gear

- Selector gear for 3rd gear, matching the original tooth count:

- 49-tooth version, or

- 47-tooth version (depending on original fitment)

These components are fitted as part of the official repair kit and updated to the latest design revision.

5. Reassembly & Adaptation

Once repaired, the gearbox is reassembled, filled with fresh oil, and the clutch and gear actuators are re-adapted using factory diagnostic procedures.

This ensures smooth engagement, correct clutch bite points, and long-term reliability.

Technical Summary

|

Stage |

Detail |

|

Gearbox Code |

0AM DQ200 (7-Speed DSG) |

|

Primary Cause |

Manufacturing deviation on 3rd-gear synchromesh |

|

Affected Parts |

3rd-gear selector fork and synchromesh assembly |

|

Repair Action |

Replace selector fork, synchromesh, and 3rd-gear selector gear |

|

Preventive Step |

Inspect mechatronic magnets and bearings for swarf or pitting |

❓ Frequently Asked Questions (FAQ)

Q: What causes the DQ200 to crunch when shifting into 3rd gear?

A: The 3rd-gear synchromesh and selector fork can wear or distort, leading to poor synchronisation and a crunching sound on gear change.

Q: Can this problem damage other gearbox components?

A: Yes. Swarf from worn parts can contaminate the gearbox oil and affect the mechatronic’s actuator readers if not cleaned during repair.

Q: Is this an electrical or mechanical issue?

A: It’s a mechanical fault inside the gearbox — not a mechatronic or software issue — although the mechatronic may log associated fault codes.

Q: How does Eco Torque fix it?

A: We replace the damaged selector fork and 3rd-gear synchromesh with updated parts and carry out full system cleaning and adaptation.

💬 Get in Touch & Share Your Experience

Have you experienced crunching or scraping in 3rd gear with your DQ200 DSG gearbox? Share your story in the comments — your feedback helps others recognise the symptoms early.

For bookings or technical advice, contact us today:

Eco Torque Ltd

Unit 1A Portland Industrial Estate

Hitchin Road

Arlesey

United Kingdom

SG15 6SG

📞 01462 835335

📧 info@eco-torque.co.uk