Introduction

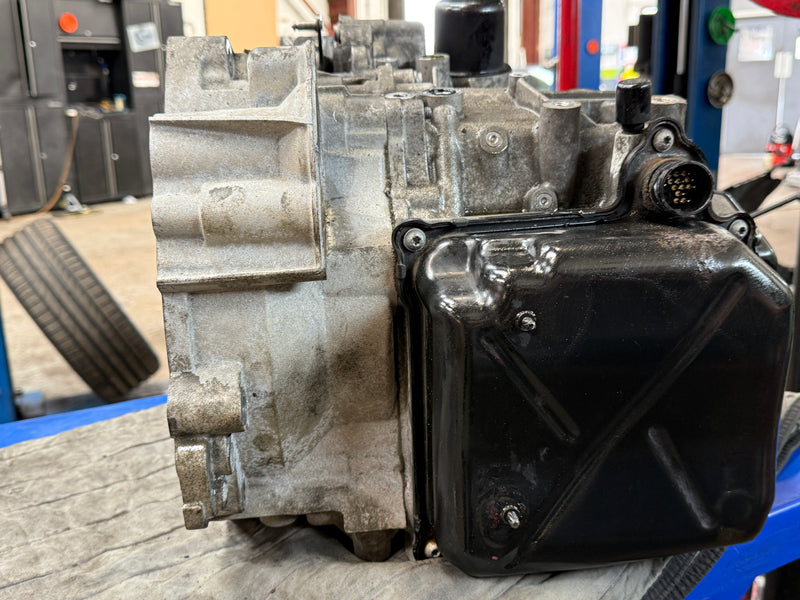

The 02E DQ250 is a 6-speed wet-clutch DSG transmission that has been used widely across the VW, Audi, SEAT, and Škoda ranges since the early 2000s. It was the first dual-clutch gearbox mass-produced by Volkswagen Group, fitted to everything from the Golf GTI to the Audi TT and Škoda Superb.

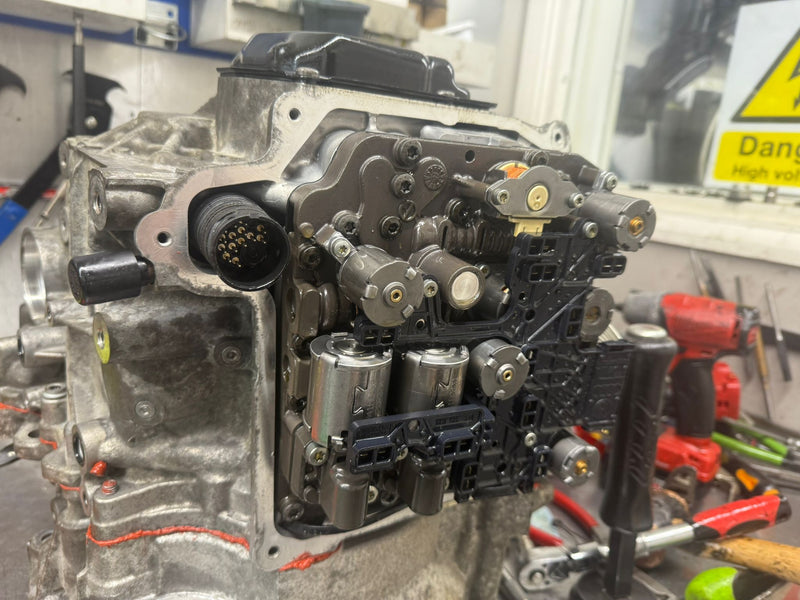

While robust in many ways, the DQ250’s mechatronic unit is one of its most common weak points. This hybrid control module — combining an ECU with hydraulic control valves — is known to fail and trigger a wide range of drivability issues.

Owners frequently report :

- Sudden loss of power or drive

- Gearbox malfunction messages on the dash

- Harsh or flaring gear changes

- Limp mode activation under load

- No communication with the gearbox ECU

At Eco Torque, we see these issues regularly in our workshop and have developed proven repair and replacement solutions.

Quick Symptoms of DQ250 Mechatronic Failure

- Harsh gear changes (often 2–3 or 3–4)

- Limp mode activation after extended driving

- Warning lights or “Gearbox malfunction” message

- Delayed engagement into drive or reverse when hot

- No communication with TCU during diagnostics

Q: What are the first signs my DQ250 mechatronic is failing?

A: Owners often notice gearbox warning lights, sudden limp mode, or jerky shifts, especially as the gearbox warms up.

Why the DQ250 Mechatronic Fails

The DQ250’s mechatronic failures usually come from:

- Solenoid valve faults — causing poor or delayed gear selection

- Sensor failures — especially input and output speed sensors

- ECU communication errors — resulting in “no comms” or CAN bus faults

- Hydraulic pressure regulation issues — leading to limp mode

- Heat damage — the mechatronic is sensitive to high fluid temperatures over time

Forums are full of complaints about owners experiencing repeated solenoid faults, loss of odd or even gears, and complete mechatronic failure requiring replacement.

Common Fault Codes for the 02E DQ250 Mechatronic

Here is a list of confirmed mechatronic-related fault codes that we frequently see logged on diagnostic scans:

- No communication possible with ECU

- CAN bus faults

- P0701 – Unit faulty

- P0716 (17100) – Transmission input speed sensor (G182), implausible signal

- P0722 (17106) – Transmission output speed sensor (G195), no signal

- P0731 (17115) – Gear 1 incorrect ratio

- P0732 (17116) – Gear 2 incorrect ratio

- P0733 (17117) – Gear 3 incorrect ratio

- P0734 (17118) – Gear 4 incorrect ratio

- P0735 (17119) – Gear 5 incorrect ratio

- P0746 (17130) – Pressure control solenoid 1 (N215), short to earth/interruption

- P0751 (17135) – Shift solenoid valve 1 (N88), short to earth/interruption

- P0756 (17140) – Shift solenoid valve 2 (N89), short to earth/interruption

- P0761 (17145) – Shift solenoid 3 (N90), short to ground/interruption

- P0766 (17150) – Shift solenoid 4 (N91), short to ground/interruption

- P0771 (17155) – Shift solenoid 5 (N92), open or short to earth

- P0776 (17160) – Pressure control solenoid 2 (N216), short to earth/interruption

- P1604 (18012) – ECU defective

- P1740 (18148) – Clutch temperature monitoring (G509)

- P1746 (18154) – Supply voltage for solenoid valves

- P1824 (18232) – Pressure control valve 3 (N217), open/short to earth

- P1829 (18237) – Pressure control valve 4 (N218), open/short to earth

- P1835 (18243) – Pressure control valve 5 (N233), short to plus

- P2723 (19155) – Pressure control solenoid valve 5 (N233), short to earth/interruption

- P2732 (19164) – Pressure control valve 6 (N371), short to earth/interruption

These codes typically point directly to mechatronic internal failure.

Eco Torque’s Repair Approach

At Eco Torque, our process for repairing DQ250 mechatronic failures includes:

- Diagnostic confirmation with VCDS or ODIS scan tools

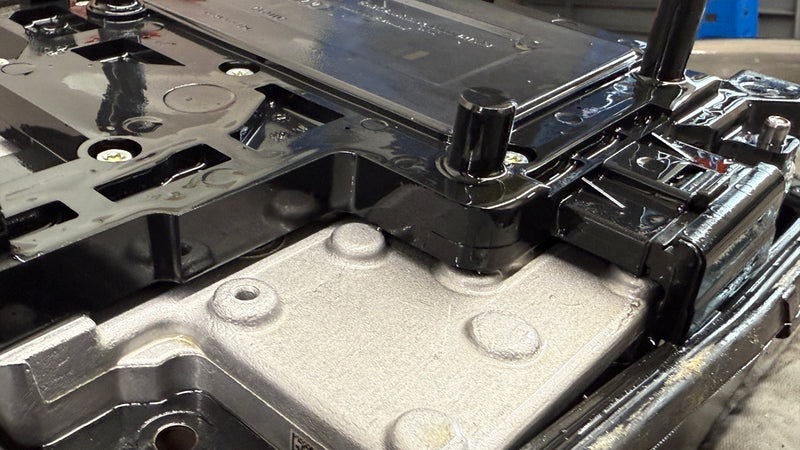

- Strip-down and inspection of the mechatronic unit

- Replacement of faulty solenoids or sensors where possible

- Full mechatronic replacement if the ECU is irreparably damaged

- Transmission basic settings and adaptations post-repair

- Gearbox fluid service to ensure long-term reliability

❓ Frequently Asked Questions (FAQ)

Q: Can the DQ250 mechatronic be repaired, or is replacement the only option?

A: Some solenoid faults can be repaired, but in many cases the mechatronic needs full replacement.

Q: What models use the DQ250 gearbox?

A: It is fitted across VW Golf GTI/R, Passat, Tiguan, Audi A3, TT, SEAT Leon, and Škoda Superb/Octavia.

Q: What are the most common symptoms of failure?

A: Harsh shifting, limp mode, warning lights, and delayed gear engagement.

Q: Does Eco Torque repair DQ250 mechatronics?

A: Yes. We offer both repairs and replacements in-house, including coding and adaptations.

💬 Get in Touch & Share Your Experience

Have you experienced DQ250 mechatronic problems? Leave a comment below with your car’s details and fault codes — your feedback helps other drivers and garages spot issues early.

For bookings or advice, contact us today:

Eco Torque Ltd

Unit 1A Portland Industrial Estate

Hitchin Road

Arlesey

United Kingdom

SG15 6SG

📞 01462 835335

📧 info@eco-torque.co.uk

1 comment

Hi I have a p271100 code, I used kick down and the car come out of gear and then gas this code, I reset the car and it runs and shifts perfectly but I didn’t kick down again so not 100% if that caused the issue, is this fixable if so how much please and what’s the problem thanks

Kind regards

Nathan

———

Eco Torque replied:

Hi

Thank you for your comment. I’ve emailed you privately with a few questions about your vehicle/transmission so we can get a clearer understanding of the issue. Once we have this information, we’ll be able to advise you more accurately on the next steps and the most effective solution.

Kind Regards

Steven Lamont Workshop Manager