Introduction

The 0AM DQ200 DSG gearbox is a 7-speed dual-clutch transmission with dry clutches, fitted across a wide range of Volkswagen, Audi, SEAT, and Škoda models.

While praised for smoothness and fuel efficiency, this unit has also been the subject of widespread complaints in owner forums and blogs, particularly relating to the mechatronic unit.

Drivers report:

- Loss of drive without warning

- Harsh, jerky shifts

- “PRNDS” flashing on the dashboard

- Vehicles entering limp mode or refusing to start

At Eco Torque, we regularly repair and replace these mechatronic units, having seen the same faults repeat across different models and years.

Quick Symptoms of DQ200 Mechatronic Failure

-

Judder and harsh 1st to 2nd gear shift at low speeds

-

PRNDS flashing or gearbox warning on the dashboard

-

No drive or refusal to engage gears (often intermittent at first)

-

Limp mode restricting available gears

-

Unreliable speed or clutch sensor readings recorded on diagnostic scan

Q: What are the tell-tale signs my DQ200 mechatronic is failing?

A: If your car struggles to select gears, suddenly loses drive, or shows “PRNDS flashing,” these are strong indicators of mechatronic failure. A diagnostic scan will usually reveal one or more of the common fault codes listed below.

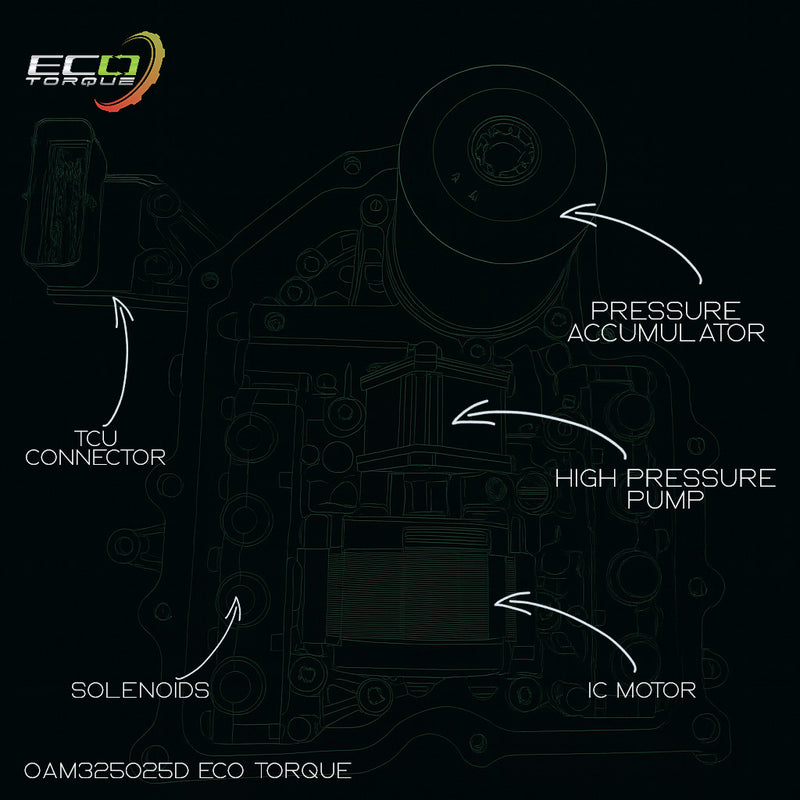

Why the DQ200 Mechatronic Fails

The mechatronic unit in the DQ200 is vulnerable due to:

- Heat damage Over heating from the ump excessively running

- Hydraulic pressure loss from internal leaks

- Sensor failures Gear position sensor

- Software issues requiring calibration or TCU updates

- Wiring issues Corrosion of the connection plus wiring harness damage

These factors often combine to trigger multiple fault codes, leading to confusion for both owners and independent garages.

Common Fault Codes for the 0AM DQ200 Mechatronic

Below is a list of the common fault codes we see here at Eco Torque on DQ200 7 Speed mechatronics.

Selected fault codes include:

- P189C – Vehicle not able to move

- P17BF – Breathing hole leak

- P1895 – Vehicle not able to move

- P176F – Hard shifting

- P175E – Intermittent error (returns after clearing)

- P0841 – Check Engine Light / intermittent no 1,3,5,7 gears

- P173D – No 2,4,6,R gears

- P072C / P072A / P072D – Loss of odd or even gears

- P178B – Vehicle not able to move

- P174D – Vehicle not able to move

- P073A / P073B – Intermittent errors, hard shifting

- P1732 / P173A / P173B / P173C – Vehicle not able to move

- P0562 – Unable to start vehicle

- P0928 – Intermittent issue, loss of drive when active

- P074A – No 2,4,6,R gears

- P1727 / P2711 – Gear slippage

- P1822 / P1850 / P1851 / P1853 / P1882 – Error codes that cannot be clearedP1741 / P177D – Hard shifting

- P1604 / P0840 / P1740 / P17C7 / P1735 / P137A – TCU internal errors

- P0660 / P0666 – Internal temperature sensor issue, no drive

- P1779 / P177A / P174C – Input shaft speed too high

- P172F / P1730 / P1731 / P1732 / P1735 / P1736 – Distance/clutch sensor issues

- P177F – Low voltage for hydraulic pump motor

- P173E / P173F / P174A / P174B / P174E – Valve electrical errors

- P0715 / P2765 – Input speed sensor errors

- P176E / P175D – Clutch opens unintentionally

- P072B – Reverse gear not selectable

- P284A – P2850 range – Shift fork or sensor damaged/contaminated

This list reflects the most commonly logged codes across workshop diagnostics and owner complaints.

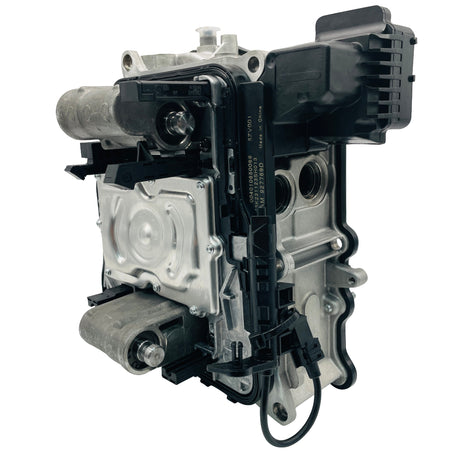

0AM Mechatronic Versions

Hardware versions

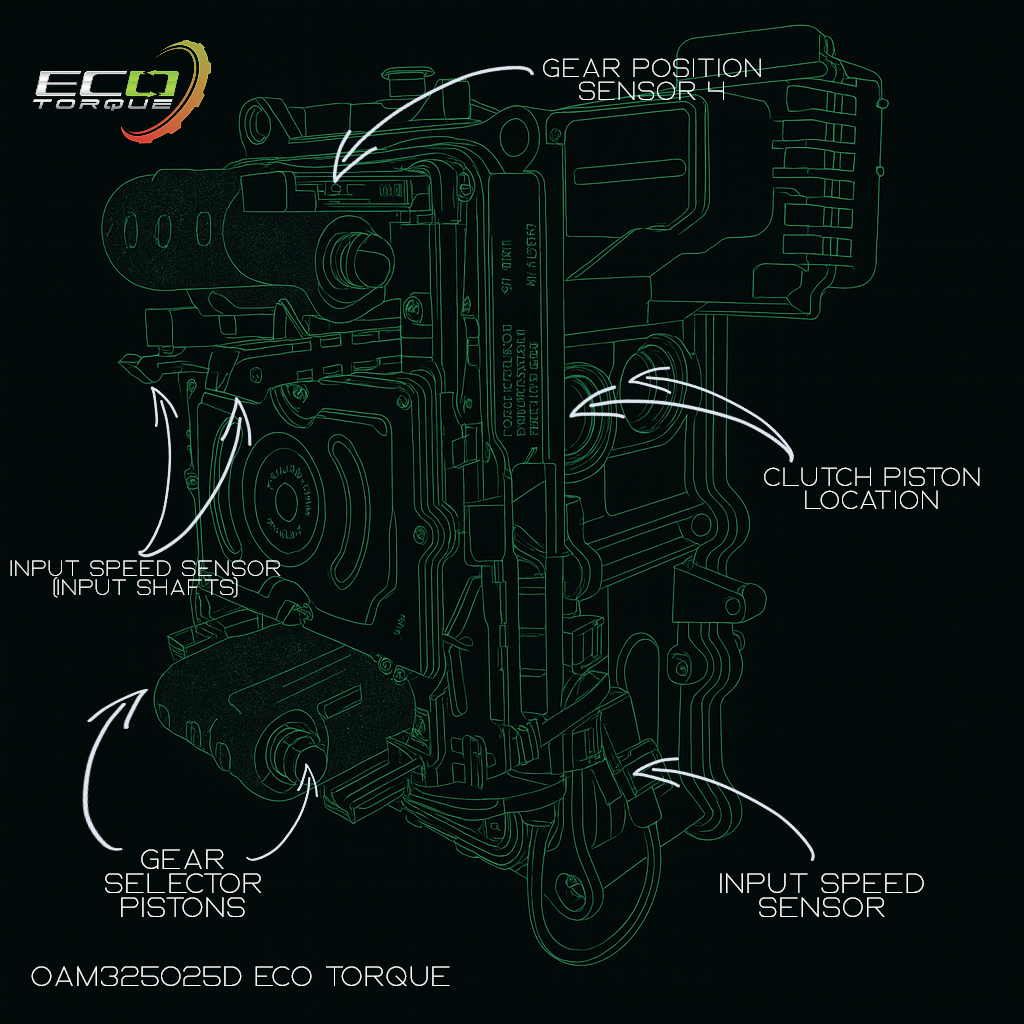

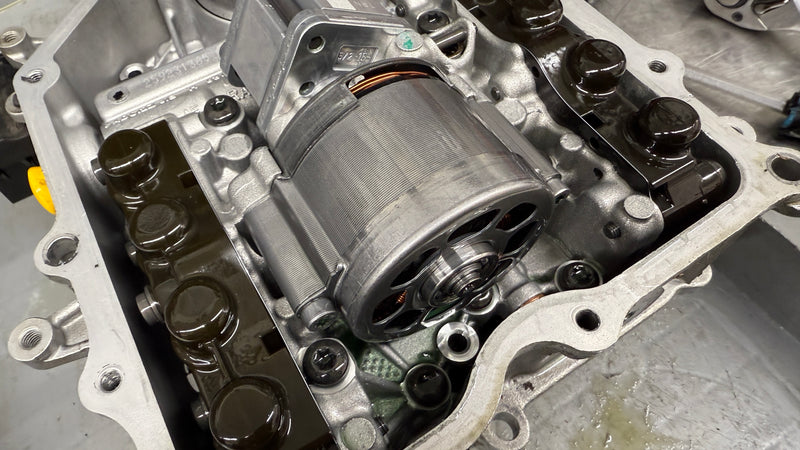

There are two main differences in hardware on the 0AM mechatronics:

- Speed sensor

- Non speed sensor

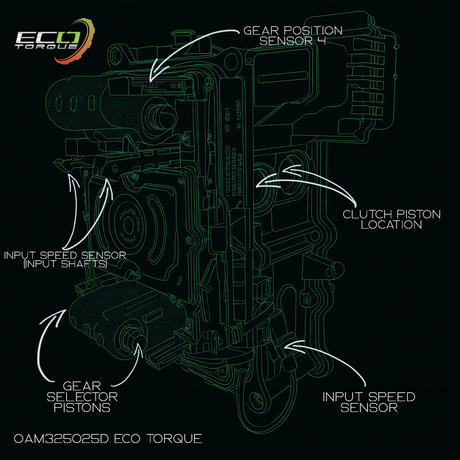

There are three speed sensors in the 0AM DQ200 mechatronic unit,. The first is located on the (D) versions and is a cable that runs on the outside of the unit and plugs into the bellhousing of the transmission. The takes a read off the ring gear on the dual mass flywheel in order to measure the engines speed.

The other two speed sensors sit on the back of the mechatronic and take a read off both of the input shafts to measure the speed of their rotation.

These two versions are not interchangeable and have specific software in order to allow each type to work.

Software Versions

There are countless software versions depending on the vehicle set up (gear ratio, engine size, location and so on). On top of this there are updates of the original software to solve particular issues or improving the overall drive,

However the two key categories which change how and what we can do on these are:

- MQB platform

- Non MQB platform

Older versions that run on the non MQB platform are much simpler to work with. We can in almost all cases preload the vehicles core software on to the unit.

The MQB platform however is much more difficult and requires the customers original unit in order to clone the vehicle software across. Security protocols are a lot to do with this and the units are essential locked to the vehicle.

If you are unsure of what version you have, simply get in contact with us and we can help you identify the unit.

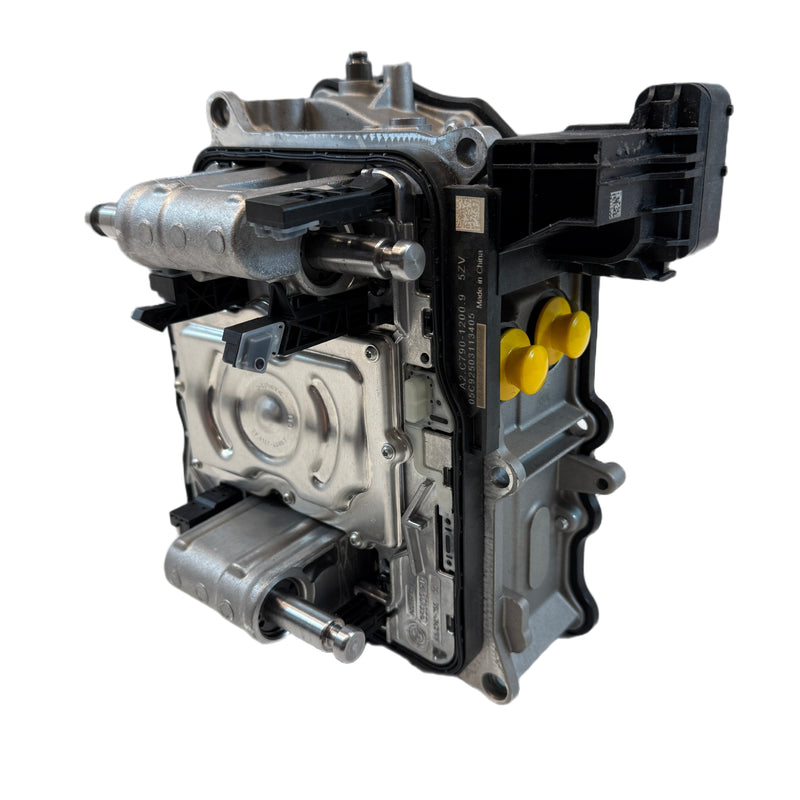

0AM Mechatronic Rebuilds & Part Quality

When it comes to DSG transmissions there is a vast range on what is and what isn't available. Transmission parts generally (especially when it comes to the UK) are almost completely unavailable, with some versions only being a complete transmission replacement.

This does however create a fantastic opportunity for companies to produce parts to offer repair solutions, without being held to the extremely high genuine prices that come with this type of transmission.

The downside of this, is quality control. Not all parts are made equal!

If you need your gearbox repaired, it is not what we would call a pleasure purchase. You do not really gain anything, you simply get back to where you were before it broke. So the temptation to spend as little as possible is very high.

However as the market is now flooded with cheap parts, it leads to poor quality repairs and additional costs for drivers.

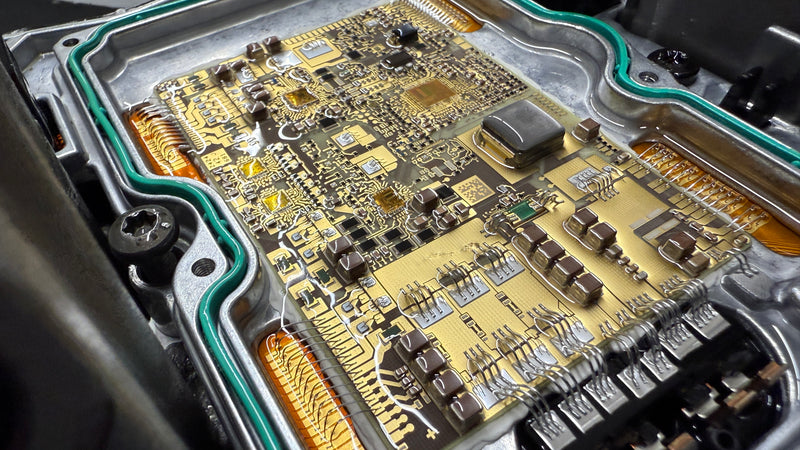

In the image above you can see the quality of the cheap eBay purchased valve body kit a customer used in an attempt to repair their mechatronic. The quality of the machining meant pressure build up was so low and resulted in the pump constantly running and overheating.

This meant the customer spent around £450 with another garage, supplying their own parts, to only have to replace the entire mechatronic, because of the additional damage caused by the low quality parts.

When it comes to these highly precise components quality is required above all else.

Eco Torque’s Repair Approach

When these issues present, Eco Torque offers:

- Mechatronic replacement depending on model

- TCU replacement and coding where required

- Basic settings & adaptations to recalibrate clutch and gear actuation

- Clutch inspection/replacement if related damage is found

- Software updates where applicable

We only use tested and proven parts to ensure long-term reliability.

❓ Frequently Asked Questions (FAQ)

Q: Can the DQ200 mechatronic be repaired, or does it always need replacing?

A: Some valve body faults can be repaired, but in many cases a full mechatronic replacement is required for reliability.

Q: Is the DQ200 recall still active?

A: Early models were subject to recalls, but most cars are now outside this window. Repairs are generally owner-funded.

Q: What are the most common fault codes?

A: Codes like P189C, P0841, P173D, and P072C are among the most frequent.

Q: Does Eco Torque repair DQ200 mechatronics in-house?

A: Yes. We carry out both repair and replacement in our Arlesey workshop, including coding and basic settings.

💬 Get in Touch & Share Your Experience

Have you experienced DQ200 mechatronic problems? Leave a comment below with your car’s details and fault codes — your feedback helps other drivers spot issues early.

For repair bookings or advice, contact us today:

Eco Torque Ltd

Unit 1A Portland Industrial Estate

Hitchin Road

Arlesey

United Kingdom

SG15 6SG

📞 01462 835335

📧 info@eco-torque.co.uk

2 comments

hi there! i want ask and get advice from sir i would like to tell my passat b7 have a problem like error code P177F..really like hydraulic motor pump problem or board hardness? i from malaysia.. thanks

———

Eco Torque replied:

Good Morning Khairul

Thank you for you comment, P177f on a DQ200 suggests there is insufficient voltage for hydraulic pump. Normally at this is stage we would look to change the TCU on the mechatronic unit as this is the electrical component which connect to the electric motor which in turn works the hydraulic pump.

Let me know if you have any other questions.

Kind Regards

Steven Lamont Workshop Manager Eco Torque ________________________________

im getting an error code of P176A00 ? What is this related to

———

Eco Torque replied:

Hi

Thank you for your comment. I’ve emailed you privately with a few questions about your vehicle/transmission so we can get a clearer understanding of the issue. Once we have this information, we’ll be able to advise you more accurately on the next steps and the most effective solution.

Kind Regards

Steven Lamont

Workshop Manager

Eco Torque

[mobilePhone]

01462 835335

[emailAddress]

info@eco-torque.co.uk<mailto:dan@eco-torque.co.uk>

[website]

www.eco-torque.co.uk<http://www.eco-torque.co.uk>

[address]

Eco Torque Gearbox & Clutch Centre , Unit 1A Portland Industrial Estate, Hitchin Road, Bedfordshire, Arlesey, SG15 6SG

[cid:6b0473db-7253-4678-8887-3f1f206accd9]

[facebook]<https://www.facebook.com/EcoTorque>

[instagram]<https://www.instagram.com/ecotorqueltd/?next=%2F>