If you are having issues with your vehicle's Haldex system or would like to know more information on what a Haldex unit is & how the system works, then this guide can help you. We will touch on some of the different Haldex faults, the different vehicles it is fitted too as well as the Haldex oil service & why it is so important.

A Brief History of Haldex

GEN I

First appearing in 1998 on the VW Golf 4Motion the Gen 1 Haldex system rolled out to the mass car market after only being patented that same year. The following year it would also appear on the Volvo S60 AWD models.

GEN II

As with all equipment in the car manufacturing world, improvements are constantly being made and by 2002 the Haldex Gen 2 made it's appearance. With changes to the solenoid operating system and the introduction of a pressure control sensor, allowed for vast traction improvements over the Gen 1 set up.

GEN III

2004 saw the Gen 3 system, which gained a check valve for the feeder pump. This gave the system the ability to be pre-emptive and give more instant torque to the clutch pack. This ability was further increase later in the Gen 3's lifespan.

GEN IV

With cost driven developments being the key factor, the Gen 4 Haldex system, further developed the pre-emptive torque design and removed the heavy differential pump system. The introduction of a hydraulic accumulator, fed by the pre-charge pump could now give more instantaneous coupling response, all kept in check by pressure reducing valves.

GEN V

In 2012 the Gen 5 Haldex unit saw the market in the VAG range. A vastly stripped down, simplified version of the AWD system was introduced further removing components from previous generations.

Haldex Pump

Common Faults

Haldex Pump Failure:

- Very common

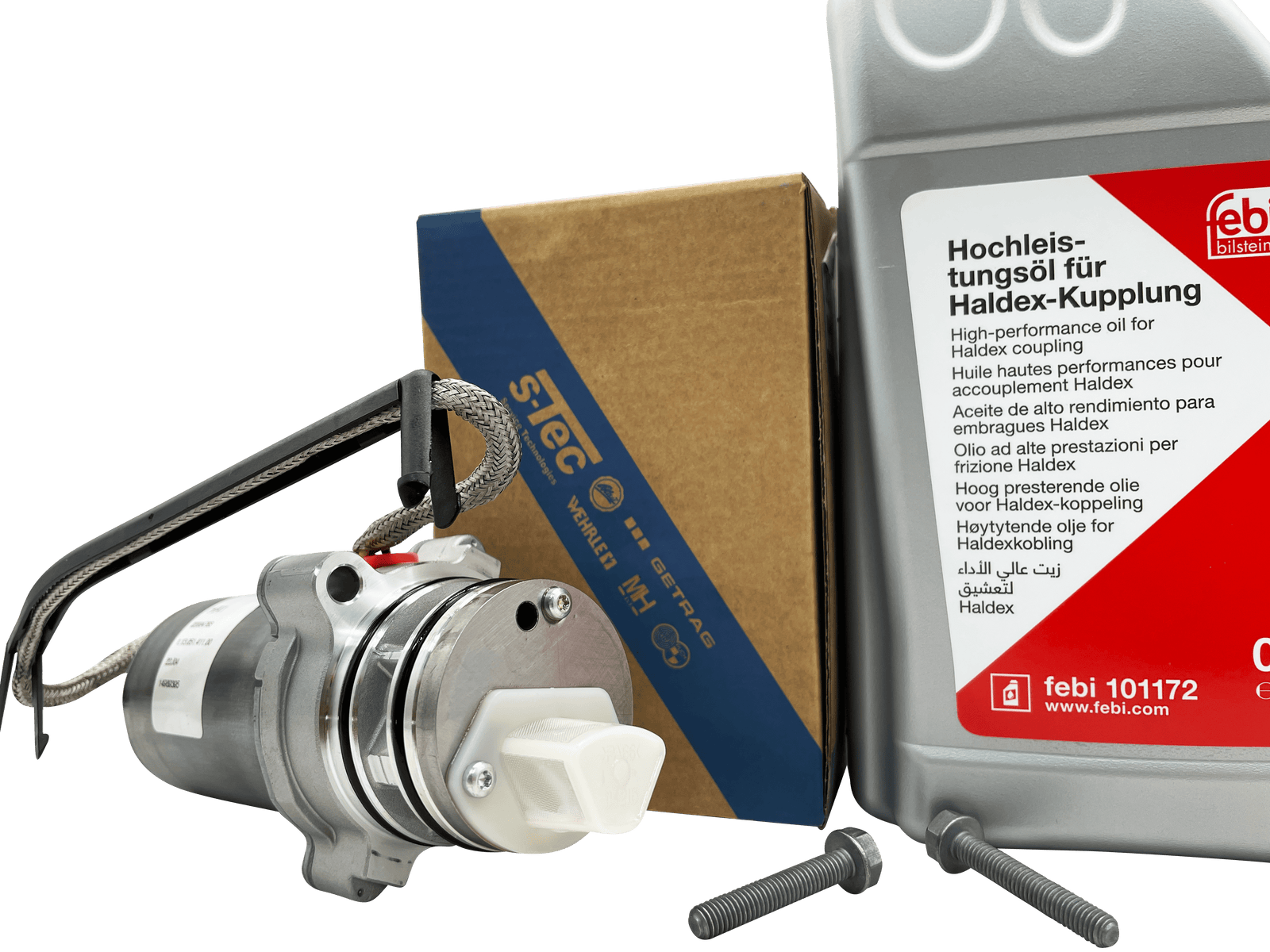

- Requires new pump and clean of Haldex system including new oil and filter gauze

This is by far the most common issue you will see with the Haldex awd system and one of the easiest to rectify. Unfortunately the system builds up with contaminants and forms a sludge which increases the strain on the pump and eventually wears out.

This can can sometimes happen without the customer realising. This is until they are in need of the 4wd system, only to realise the Haldex system does not work, and they only have front wheel drive.

You may some of the following fault codes relating to Haldex pump failure:

- 00448 - Haldex Clutch Pump V181 - Lower Limited Exceeded. (Gen 4)

- 00448 - Haldex Clutch Pump V181 - Open Circuit/Defective. (Gen 4)

- 16670 - All Wheel Drive - Mechanical Failure. (Gen 5)

- 16671 - Pump For Haldex Pump - Internal System Fault. (Gen 5)

- 16666 - Pump For Haldex Clutch - Open Circuit. (Gen 5)

- 16668 - Pump For Haldex Clutch - Mechanical Failure. (Gen 5)

When replacing pumps it is vital to renew the Haldex filter and oil. This will prevent the new pump from failing within a very short period of time.

Haldex Controller

Common Faults

Haldex Controller Water Damage/Corrosion:

- Very common

- Requires strip down of Haldex controller & repair or replacement of unit

Water ingress and corrosion damage on the Haldex Gen 2, Gen 3, Gen 4 & Gen 5 controllers are unfortunately very common . The damage to the circuit board can cause an array of fault codes, some of which can lead to a misdiagnosis of the pump and vice versa.

You may have some of the following fault codes relating to Haldex controller failure:

- 00003 - Control Module Faulty - Defective

- 00448 - Haldex Clutch Pump V181 - Defective

- 01324 - All Wheel Drive Module - No Communication/Signal

- 02248 - Valve For Controlling Clutch Operating Angle - Defective

- 02249 - Sensor For Oil Pressure / Oil Temperature - No Signal

- 16347 - Control Module - EEPROM Error

- 65535 - Internal Control Module Memory Error

Haldex Coupling

Common Faults

Haldex Coupling Wear:

- Uncommon

- Requires replacement Haldex coupling with oil and filter

Faults with the Haldex coupling itself isn't very common. Vehicles modified outside of the manufacturer's parameters do see issues as the unit is only rated to a certain threshold. Failing Haldex pumps and controllers will also shorten the lifespan of the system.

Haldex Oil Change

Common Faults

Haldex Oil Change:

- Very Common

- Lack of Haldex oil & filter servicing leads to damage to pump

The importance of an oil an filter service is crucial, and can prevent almost all of the Haldex problems listed previously in this article. It is an item normally overlooked as most customers do not know it is even required on their vehicles.

A thorough clean is required, by removing the pump to clean any gunge that accumulates on the pump, as well as new oil and filter gauze where applicable. This should be done every 20,000 miles to ensure that excessive wear to the pump does not occur.

VW Haldex (VAG)

As we will touch briefly on the manufacturers that use the Haldex system, the VAG range have numerous models fitted with both front and rear Haldex systems. The main issues with Audi Haldex and VW Haldex is the lack of driver warning when there is an issue with the system. Drivers can do thousands if not tens of thousands of miles and not realise there is an issue with the vehicle.

This issue is surprising as the VAG range is usually very strong when it comes to onboard diagnostics and information presented to the driver. The issue is also partly with drivers and the modern day car. Most if not all drivers know the basics when it comes to servicing a vehicle, they know it needs engine oil and various filters.

However as the modern day vehicle becomes even more advanced, most drivers do not know the technology in their cars, let alone maintenance that is required for it. We see this time and time again dual clutch transmissions as well as Haldex units. There also seems to be a very troubling pattern emerging where main dealerships as well as independent garages who regularly service their customers vehicles, are missing these important component service points.

We see many customers with full main dealer service history but know entries for Haldex oil servicing. This is sometimes missed by independent garages due to the lack of information on the subject and requirements rather than any sort of negligence.

Freelander 2 Haldex Unit

A very common enquiry we get is from the owners of the Freelander 2 having Haldex problems. The Haldex unit is fitted on a few different versions of the Land Rover range, but this seems to be the most common one we see.

Communication errors with the rear differential control module (RDCM) are normally seen with the accompanying fault codes:

- RDCM - P0961-02

- ATCM - U0437-94

- ABS - U0114-68

- P1889 - (Haldex Pump Fault)

Haldex pump failure is also common on the Freelander 2 as well as the other Land Rover models. It is important to complete the Haldex oil change as required including the filters to prevent premature failure.

Ford Kuga AWD

If you own a Ford Kuga you may be reading this because you have seen the AWD malfunction warning light on your dashboard. Or you may have been in the situation where the Haldex 4WD system would of got you out of a spot of bother, to notice that you've only got the front wheels providing power.

This is another instance of the "sealed for life" failure that so many manufacturers fall short on. The Ford Kuga AWD systems are not sealed for life and simple maintenance has the potential to save very expensive repair work in comparison.

Common fault codes for faults with the Haldex controller:

- P0606- ECU Short or Open Circuit

- P0960 - PCS Control Circuit Open

- P0961 PCS Control Circuit Range Performance

The most common issue with this system, as with all Haldex units is the pump, this brings up an P1889 fault code when the vehicle is scanned.

Haldex AWD Volvo

Volvo systems run a very similar pattern and fault diagnosis as the Land Rover models and Ford Kuga. These show a visual warning on the dashboard (Anti Skid Service Required) when there is an issue with the Haldex unit, or differential electronic module, as Volvo has named it.

Common Fault codes:

- DEM - 0002

- DEM - 0003

- DEM - 0006

- DEM - 0007

- DEM - 0008

- CEM - 1A64

- BCM - 00094

- BCM - 00095

The last three fault codes on this list are communication errors with the central control module (CEM) and the body control module (BCM). These often appear due to the lack of signal from the Haldex controller and are a good indication that the fault lies there.

If you think your vehicle might be suffering from a Haldex fault and as with all transmission issues, it is best to get it looked at straight away as it could save the customer substantial amounts on their repair bill.

Eco Torque offer an initial electronic diagnostic service with our main dealer equivalent machine. This shows us live data from the Hladex controller as well as a report for the customer to see the fault codes with the vehicle. This essential first step is £90 including VAT and takes around 1 hour to complete.

All of our Haldex repairs or reconditioned units come with a 12 Month 12'000 Mile Warranty. We also offer 0% finance through Omni Capital Finance* to spread the cost of the repair bill. Eco Torque can also provide courtesy cars** as well as recovery*** of your vehicle.

Need Workshop Repairs?

Contact our workshop today on 01462 835335 or email us on info@eco-torque.co.uk, if you need help with your gearbox.

Need Haldex Parts?

Find our Haldex product range here.

Get In Touch

Have you experienced any problems with your car? We’d love to hear from you! Share your feedback by leaving a comment below. We look forward to learning about your thoughts and experiences.

For specific enquiries, please reach out to us directly using the contact details provided below.

For more information

contact Eco Torque today

Tel: 01462 835335

Email: info@eco-torque.co.uk

Eco Torque Ltd, Unit 1A Portland Industrial Estate, Hitchin Road, Arlesey, United Kingdom, SG15 6SG

5 comments

Hi

On a Skoda Superb 2012 4×4 2,0tdi with fault code on solenoid valve under haldex controlunit.

Is it possible to change it without complete repair set?

My last comment was on a Land Rover evoque 64 plate with 124000 miles. No dash warning lights.

Feels like half shaft wind up as if the diff is locked on tight turns. Complete service carried out 12000 miles ago. Fault only noticed in last 1000 miles. Help please.

———

Eco Torque replied:

Hi

Thank you for your comment, i have emailed you privately with some questions regarding your car to help better diagnose the problem.

Kind Regards

Steven Lamont Workshop Manager

Es posible que se atasque el sistema trasero debido al fallo en la bomba?

Freelander 2 haldex problem 14 reg it is grabbing on a tight turn no lights on dash just had it serviced I was unaware of 20.000 mile service in has done 82 ooo I wait your comment thanks