Clutch and Flywheel Replacement

Eco Torque specialises in clutch services, providing a comprehensive selection of clutch repairs and flywheel replacement solutions for your vehicle.

We strive for efficiency, often completing clutch and flywheel repairs or replacements on the same day. Understanding the inconvenience of being without a vehicle, we focus on minimising your downtime.

Regardless of the nature of your clutch and flywheel problems, Eco Torque is equipped to assist you.

How it works

Frequently Asked Questions

Clutch

How much does a clutch replacement cost?

How much does a clutch replacement cost?

The price to replace a clutch varies between manufacturers and even models. The price also depends on the set up of the clutch system; does it have a release bearing or a concentric slave cylinder? The average cost to replace a clutch kit is around £450.

How long does a clutch last?

How long does a clutch last?

The lifespan of a clutch depends on many factors. We have seen some cars come in for their first clutch replacement on 200,000 miles. The average is around 100K - 150K miles. Riding the clutch, stop/start journeys and contamination however, will drastically reduce the lifespan of a new clutch kit.

How long will a noisy release bearing last?

How long will a noisy release bearing last?

In short, not long. The clutch release bearing deals with an incredible amount of operational stress for such a small component. It presses on the diaphragm of the clutch separating the gearbox and engine. Like all transmission issues, it is best to get it sorted as soon as possible as the cost can increase drastically.

What are a worn clutch symptoms?

What are a worn clutch symptoms?

Worn clutch symptoms can vary. You may have some or all of these faults. Clutch slipping, loss of drive, burning smell, clutch judder, sticky clutch, clutch pedal on the floor or noise when pressing foot on clutch pedal.

What is a hydraulic clutch?

What is a hydraulic clutch?

The operation of the clutch system on passenger and light commercial vehicles consist of two types of designs. Hydraulic and cable. A hydraulic clutch uses clutch fluid to pressurise an external slave or concentric slave cylinder to disengage the clutch.

The cable operated system uses a clutch fork on a fulcrum to push a release bearing onto the clutch plate and disengage the drive.

What is riding the clutch?

What is riding the clutch?

Riding the clutch generally happens in two different ways. The first, which is more common, is when the driver does not bring their foot completely off the clutch pedal, or off the clutch pedal quick enough when engaging the accelerator. This gives a distinctive over revving from the engine followed by a lurch or kangaroo forward as the clutch is finally fully engaged.

The second is less common but occurs when the driver rests their foot on the clutch pedal when driving, which can cause partial disengagement and overheating, resulting in premature wear.

Flywheels

What does a flywheel do?

What does a flywheel do?

The flywheel is essentially an energy storage device. Attached to the crankshaft, the rotational spin of the engine is converted into kinetic energy via the flywheel. Without going into the science of kinetic energy, the mass of flywheel keeps and stabilises the engine rpm.

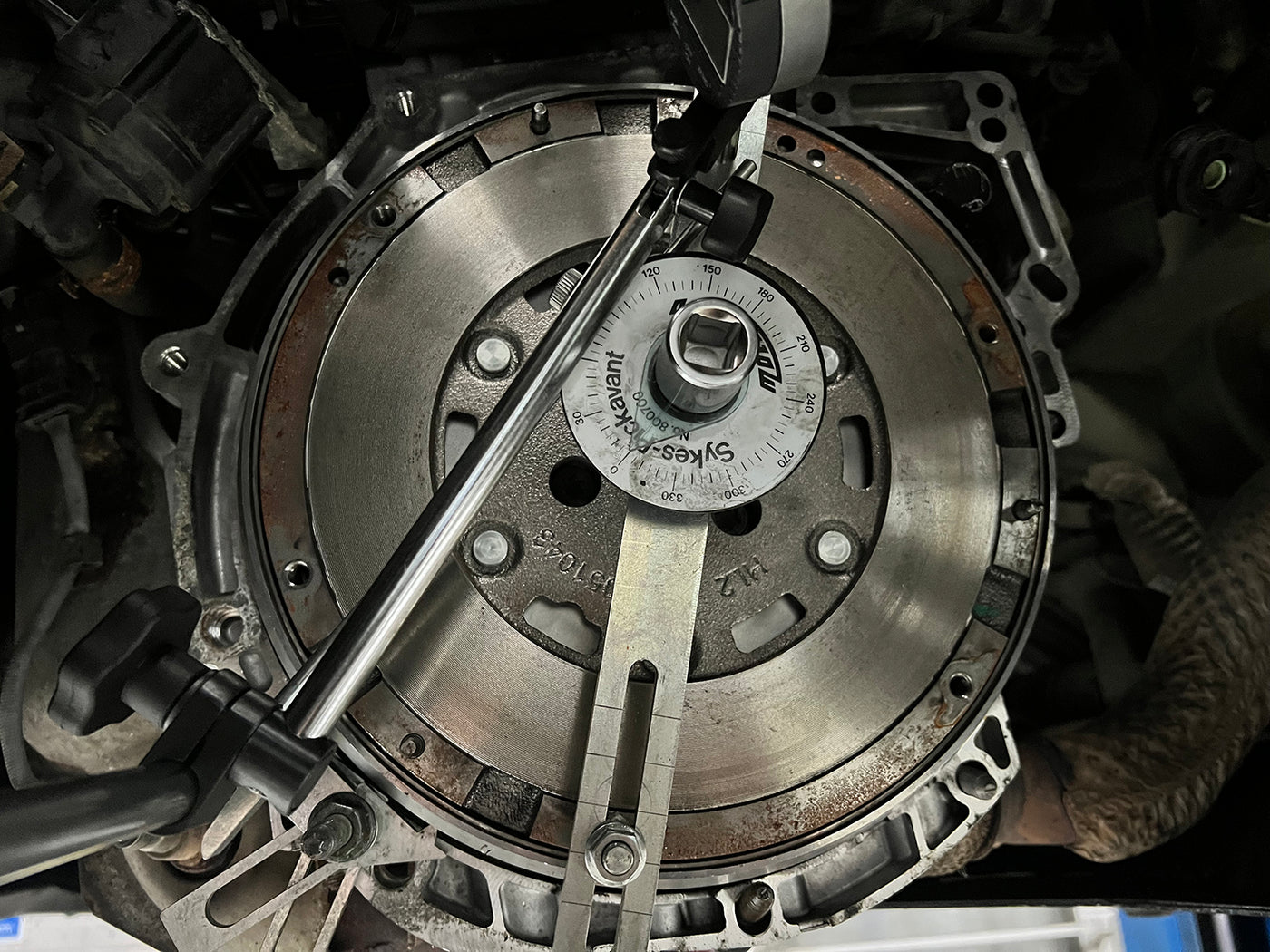

What is a dual mass flywheel?

What is a dual mass flywheel?

A dual mass flywheel is a twin flywheel system, having a larger crank mounted flywheel with a lighter, inner, sprung loaded flywheel to which the friction plate of the clutch comes into contact. The reason behind this design is the smooth engagement of the clutch on higher torque vehicles along with an improvement on MPG.

What are the symptoms of a worn dual mass flywheel?

What are the symptoms of a worn dual mass flywheel?

A worn dual mass flywheel can cause heavy vibration throughout the car. It can also produce a rattling sound, either constantly, or at certain points when the clutch pedal is pressed down slowly. A vibration through the clutch pedal can also sometimes be felt.

What is a worn dual mass flywheel noise?

What is a worn dual mass flywheel noise?

A worn dual mass flywheel can make a heavy metal rattling noise. It can also make a tapping sound and is normally quite distinctive. If in doubt visit your local mechanic or clutch specialist immediately.

Do I need to change the dual mass flywheel with the clutch?

Do I need to change the dual mass flywheel with the clutch?

Not necessarily! There is a reason that LUK, the largest manufacturer of flywheels, has a measuring tool to see how badly worn a dual mass flywheel is. Their official line on the subject, is that a dual mass flywheel should last the life of two clutches. This is not always the case unfortunately however to say that they need replacing regardless, is simply not true and a very bad up-selling technique by some companies!